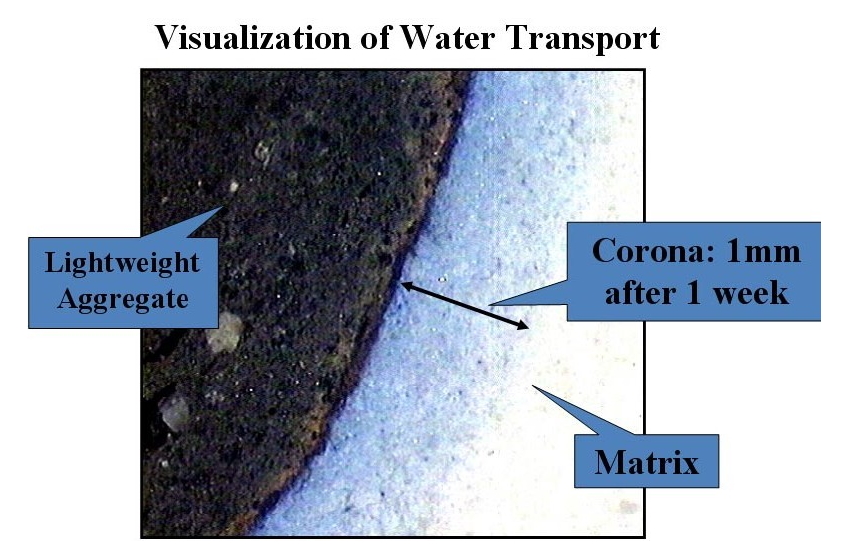

The American Concrete Institute (ACI) defines Internal Curing as supplying water throughout a freshly placed cementitious mixture using reservoirs, via pre-wetted lightweight aggregates, that readily release water as needed for hydration or to replace moisture lost through evaporation or self-desiccation.

Saturated Norlite lightweight aggregate may be substituted for normal weight aggregates to provide internal curing in concrete. Low water to cementious ratio concretes are vulnerable to self-desiccation and early-age cracking, and benefit significantly from the slowly released internal moisture. Field experience has shown that high strength concrete is not necessarily high performance concrete. A frequent, unintended consequence of high performance and many other concretes is early-age cracking. The addition of Norlite for internal curing can help to significantly reduce or eliminate cracking.

Numerous bridges have utilized Norlite saturated lightweight aggregate fines to improve the characteristics of High Performance Concrete Bridge decks. The internal curing provided better hydration of the cementitious fraction of the concrete. Moisture is slowly released from reservoirs of absorbed water within the pores of the lightweight aggregate as the binder demands it. This additional curing helps to reduce early age cracking caused by drying, autogeneous, and thermal effects. Reduction of cracking helps to improve durability and service lives of the structures.